Close

Choosing the right wiring solution is one of the most important decisions in any electrical setup, whether it’s for homes, offices, factories or commercial projects. In Dubai, where industries and construction projects are constantly growing, electrical systems must be efficient, safe and adaptable. This is where the question arises: When to Use Flexible Wires Instead of Standard Control Cables?

In this blog, we will provide a clear overview of the differences between flexible wires and standard control cables, their unique applications and the situations where flexible wires can be a smarter choice. You will also learn about their benefits, limitations and how businesses in Dubai can take advantage of the latest wiring solutions to meet safety and efficiency standards. By the end, you will know exactly when flexible wires are more suitable and why making the right choice is essential for long-term performance.

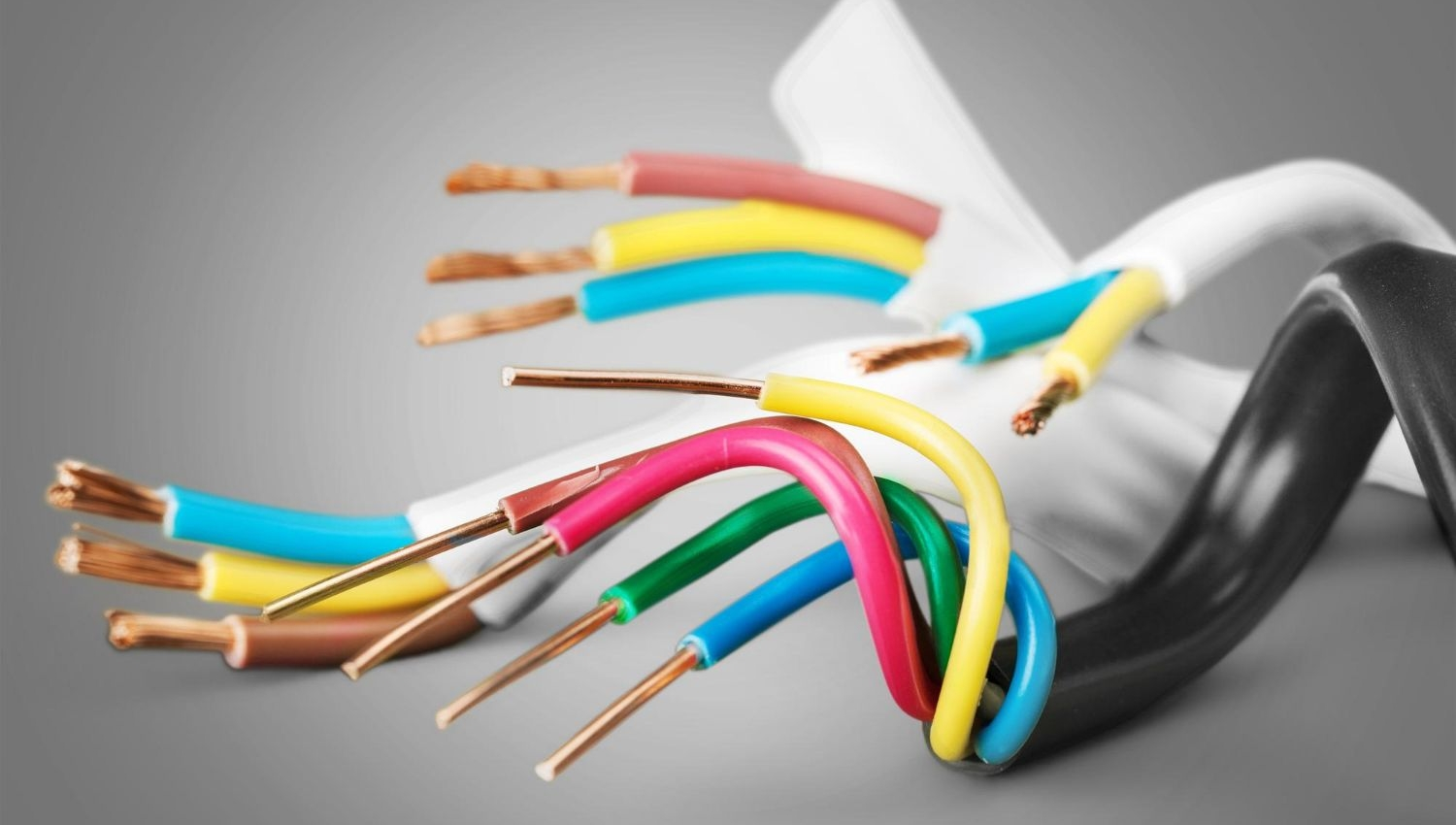

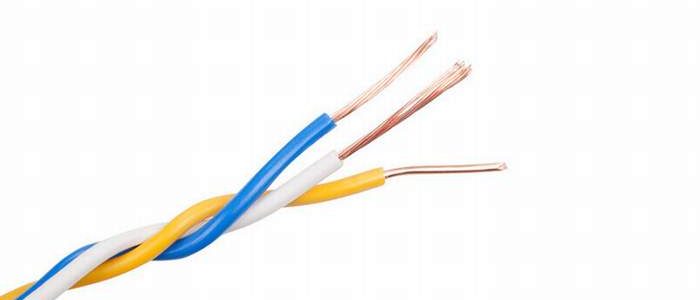

Flexible wires for control cables are special types of electrical wires that are used to carry control signals or power to equipment, such as machines, motors, switches and panels. The word “flexible” means they are easy to bend and move, making them perfect for systems where wires need to handle frequent motion or installation in tight spaces.

They are used in low voltage control systems and are made with fine copper strands for extra flexibility. These wires are often covered with PVC or other protective insulation , making them durable in different environmental conditions.

Flexible wires are designed with multiple fine strands of copper that make them more bendable and versatile compared to solid or thickly stranded control cables. Their structure allows them to withstand repeated movement, vibrations and bending without breaking.

These properties make them an excellent choice for industries and environments where wires need to move or be adjusted regularly.

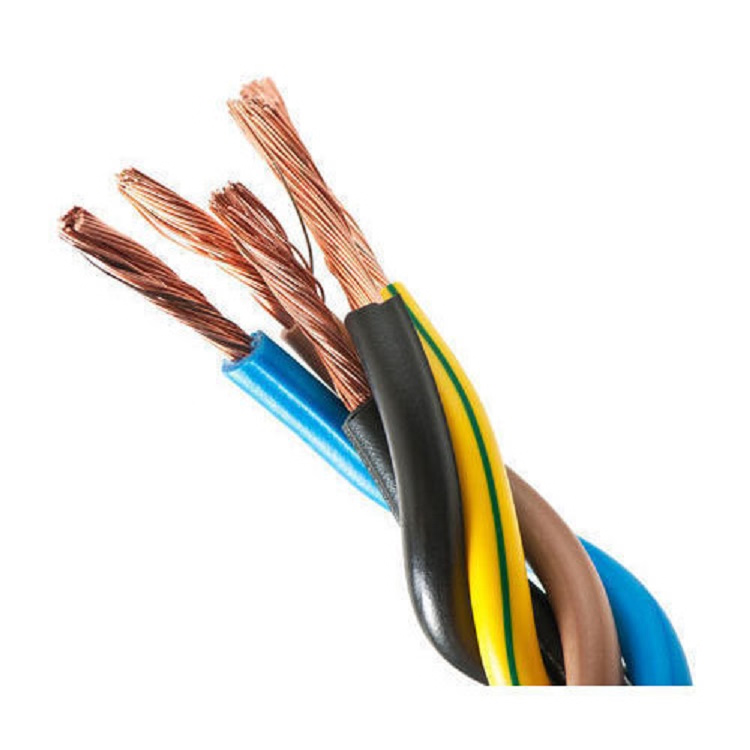

Standard control cables are typically used in fixed installations where wiring does not need to move once installed. They are stronger in terms of stability but less adaptable in terms of flexibility.

While they are reliable, they may not perform well in applications where movement, bending or vibrations are constant.

Feature | Flexible Wires | Standard Control Cables |

Flexibility | Highly bendable, ideal for movement | Rigid, suitable for fixed use |

Durability | Great under vibration and bending | Strong in stable environments |

Installation | Easy in compact or moving systems | Best for structured layouts |

Cost | Slightly higher for advanced types | Generally cost-effective |

Applications | Robotics, appliances, dynamic machinery | Panels, automation, power distribution |

Now let’s answer the main question: When should you choose flexible wires over standard control cables?

Flexible wires are essential in machines or robots that move continuously. Standard cables would wear out quickly under constant bending, while flexible wires maintain performance.

Factories, workshops, and construction sites often have equipment that vibrates during operation. Flexible wires handle vibrations better without breaking.

Household and industrial appliances like vacuum cleaners, drills or welding machines need wires that move easily. Flexible wires provide safety and convenience.

When wiring must pass through small or curved spaces, flexible wires make installation easier compared to stiff control cables.

Facilities that require regular inspection or rewiring benefit from flexible wires because they can be moved and adjusted without damage.

Dubai’s industrial and commercial sectors are adopting modern wiring solutions to improve safety and efficiency. Flexible wires provide unique advantages:

While flexible wires are extremely useful, they also have some limitations:

Before deciding, think about:

As Dubai grows into a smart city, wiring solutions are evolving:

To sum up, knowing when to use flexible wires instead of standard control cables can save you time, money and effort while ensuring safety and efficiency. Flexible wires are best for moving, vibrating or compact applications, while standard control cables remain the right choice for stable, fixed installations. The key is to match the wiring type with your project’s needs.

At Levit Electric, we provide high-quality wiring solutions designed to meet Dubai’s modern requirements. Whether you need flexible wires for dynamic systems or control cables for industrial installations, our expertise ensures you get the right solution for long-lasting performance and safety. By choosing the right wiring system today, you secure a reliable and future-ready electrical setup for tomorrow.

WhatsApp us