Close

Industrial automation relies on precise control, seamless connectivity, and efficient power delivery to keep machines and processes running smoothly. A critical component that supports this functionality is the multi-conductor flexible cable, a type of cable designed to carry multiple signals or power lines within a single, durable sheath. These cables not only simplify wiring but also provide flexibility, reliability, and protection against harsh industrial conditions. In this blog, we will discuss understanding the role of multi-conductor flexible cables in industrial automation, covering their features, benefits, applications, installation best practices, maintenance tips, and how they contribute to safer, more efficient, and cost-effective automation systems. By the end of this guide, readers will have a clear understanding of why these cables are essential and how to make the most of them in industrial setups.

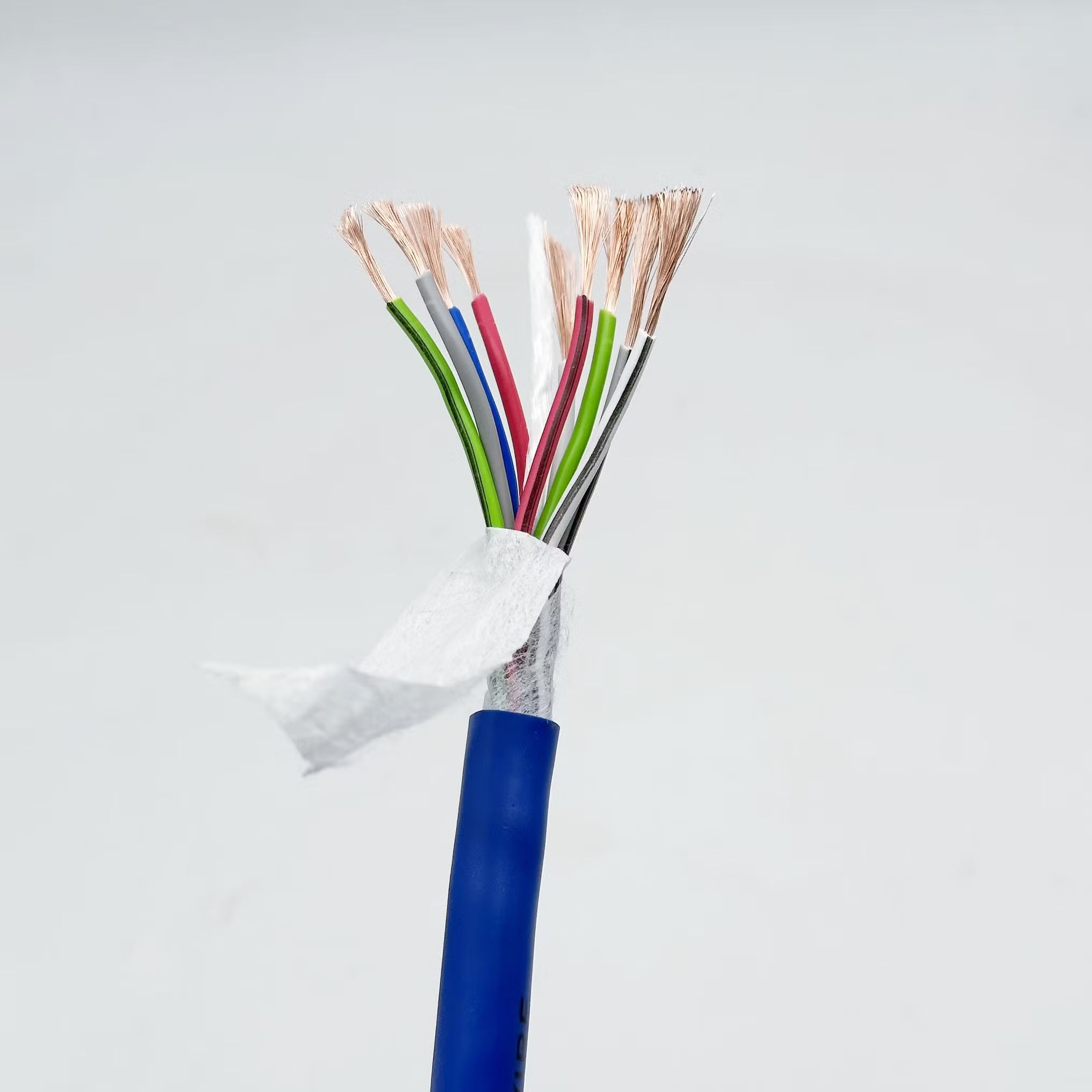

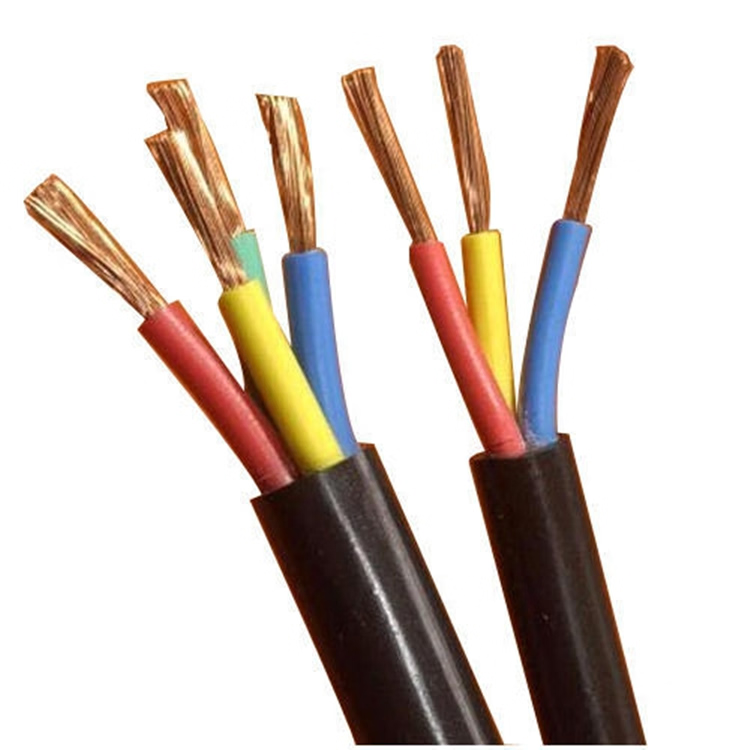

Multi-conductor flexible cables consist of several insulated wires grouped together inside a single outer sheath. Each conductor within the cable can transmit power or signals between devices, controllers, and machines. Unlike standard cables, they are designed to handle bending, movement, and vibrations while maintaining electrical performance.

Key features include:

These characteristics make multi-conductor flexible cables ideal for dynamic industrial environments where machines are constantly in motion and precise signal transmission is critical.

Flexible cables allow technicians to route them through tight spaces, around machinery, and through conduits without stressing the conductors. This makes installation faster and reduces the risk of damage.

By bundling multiple conductors into a single cable, clutter is minimized, wiring is more organized, and future troubleshooting becomes simpler.

Industrial environments often expose cables to vibrations, temperature fluctuations, oils, and chemicals. Multi-conductor flexible cables are built to withstand these conditions, ensuring long-lasting performance.

Shielded and insulated designs protect against electromagnetic interference (EMI) and crosstalk, maintaining accurate and consistent signal transmission across automation systems.

Fewer individual wires mean reduced material and labor costs. The organized layout also simplifies maintenance and reduces potential errors, saving time and money.

Multi-conductor flexible cables are widely used in industrial automation for:

Their versatility makes these cables essential in industries ranging from manufacturing to energy production, packaging, and logistics.

Proper installation ensures the cables perform reliably and reduces the likelihood of downtime or faults.

Regular maintenance not only prolongs the life of the cables but also protects the connected machinery and ensures uninterrupted industrial operations.

By following best practices and choosing high-quality cables, these challenges can be effectively mitigated.

To sum up, multi-conductor flexible cables are essential for efficient, safe, and reliable industrial automation. They combine multiple conductors into a single flexible cable, simplifying installation, reducing clutter, and ensuring accurate signal transmission. Their durability, flexibility, and resistance to harsh conditions make them ideal for dynamic industrial environments.

For businesses seeking reliable automation solutions, partnering with experts like Levit Electric ensures access to high-quality multi-conductor flexible cables that meet industrial standards and operational needs. Proper selection, installation, and maintenance of these cables can enhance system reliability, improve safety, and increase operational efficiency, supporting smooth and productive industrial operations.

WhatsApp us